I almost bought a big floor loom last week.

No lie, I have been stalking the used fiber equipment pages here, here, here, here, here, here, here, here and here. A $150 loom popped up in Raleigh and I was ready to go get it. But my studio was not as ready. This thing was about a foot wider and 50 lbs heavier than what I really want. I was going to have to do some major rearranging put a piece of heirloom furniture in storage, possible buy a new desk and it began to be not the loom for me. So I let it go and will continue to save and scour the listing daily.

In the mean time I am Working with the wonky table loom I have, as well as exploring what exactly can be considered a loom. Because really weaving can be done without one. There are some crazy innovative substitutes you can make for a loom to get your weave on.

In this week’s live cast, I shared several crazy good loom hacks. check it all out here.

**the sound was not working for the first 1:54 minutes of the video….The video should start at the 1:54 mark, if not you might need to skip ahead to the 1:54 mark**

Sign Up for the UrbanGypZ Fiber Arts Collective

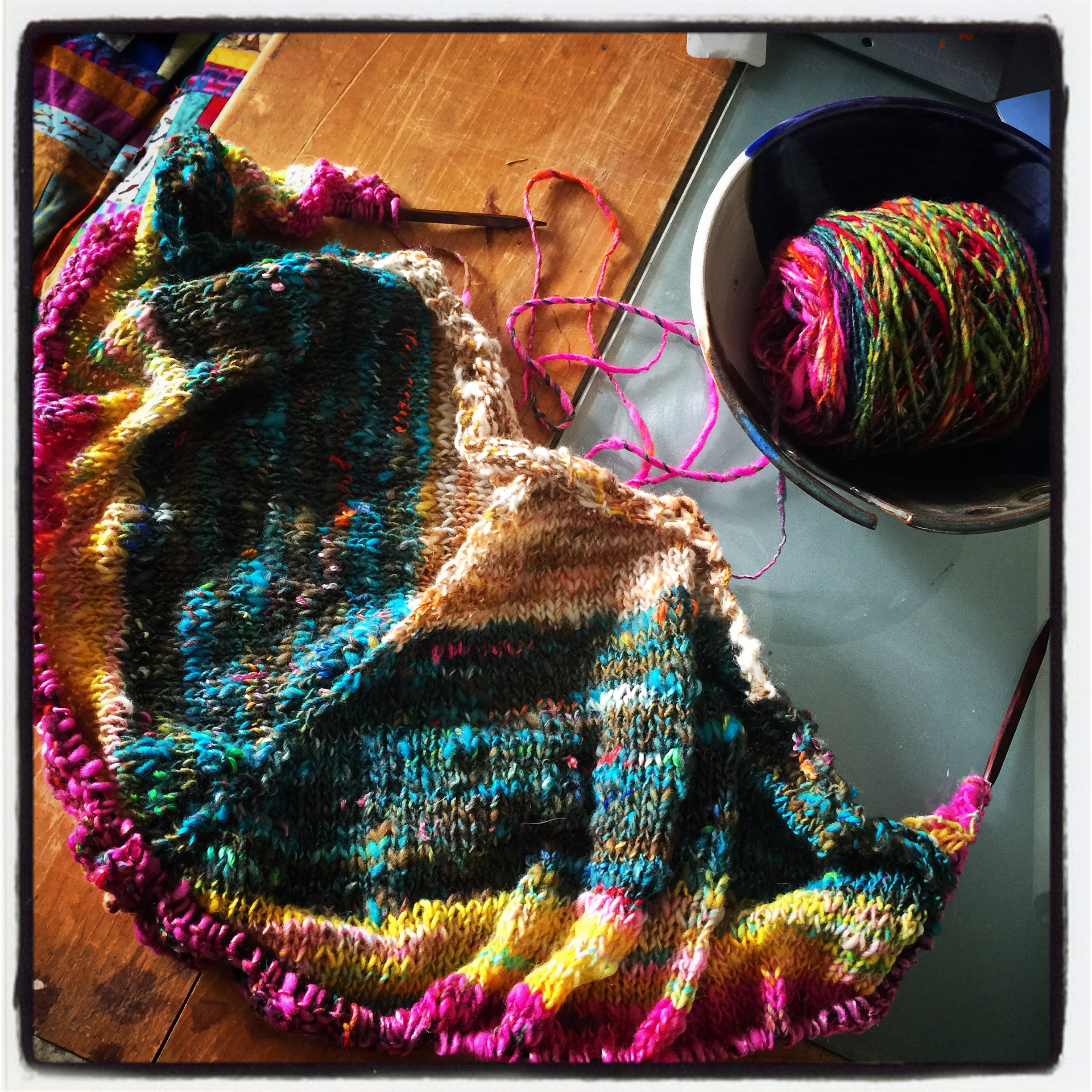

Fiber artist Stacey Budge-Kamison AKA UrbanGypZ lives and works in Cary NC. She can also be found knitting in public, hammering out her latest e-course at local cafés and spinning yarns in her booth at her favorite arts festivals. A designer at heart, Stacey has decided that her mission is to help fellow knitters, crocheters, weavers and felters embrace their own style and creativity by exploring fiber art as it is a part of their everyday life and helping them embrace the title of artist no matter where they are in their journey.

Fiber artist Stacey Budge-Kamison AKA UrbanGypZ lives and works in Cary NC. She can also be found knitting in public, hammering out her latest e-course at local cafés and spinning yarns in her booth at her favorite arts festivals. A designer at heart, Stacey has decided that her mission is to help fellow knitters, crocheters, weavers and felters embrace their own style and creativity by exploring fiber art as it is a part of their everyday life and helping them embrace the title of artist no matter where they are in their journey.

Right now not weaving but spinning. Hubby is working on my fiber chic she shed. Once complete all the looms will move out there.

Pin looms: I rubberband two blocking board tiles together, and stick pins in ’em. Check out books by Helen Banes.

Sticks: google for directions on how to clean them up. I soak them for 2 days in washing soda, and then use a variety of tools to strip any remaining bark. Bark rots, and harbors all sorts of life forms you don’t want in your weaving. The stick itself becomes a work of art, and you have the option of staining or dying it. Yes, fabric dye.

Giant frame looms: I got a mobile clothes rack for macrame, but it occurred to me that I could wrap warp around the rack rod and the base. Not sure how to keep the dent even, but can probably solve any problem with enough duct tape.

Picture frame looms: go to an art supply store and buy canvas stretchers.

Note: brads are hard to hammer in unless you have extraordinarily soft wood. Next frame loom I make (yes, I’ve made one), I’m gonna try using a dremel to cut grooves. Drill holes down the verticals at 2″ intervals and attach the horizontals with bolts & wing nuts. Allows you to adjust the height of the loom. Not sure adjusting the width buys you anything.

Thanks for the Foamular idea. Gonna run right out and buy some. =) =) =)